When it comes to keeping machines running smoothly, PLC (Programmable Logic Controller) troubleshooting is every automation engineer’s rite of passage. Imagine being the unsung hero, the one who finds that glitch in the matrix—yes, it’s like being Neo but in a high-vis vest and safety goggles! Fault finding in PLCs isn’t just a skill; it’s an art form, and today, we’ll dive into the world of troubleshooting, with practical examples, and tips.

First Things First: Understanding Why PLCs Fail

1. Electrical Noise

PLC systems are incredibly sensitive to electrical noise, which can interfere with signals and cause… you guessed it, glitches! It’s like static on a radio, and you’re left wondering, “Is it broken, or just throwing a tantrum?” A real-world scenario might be when a motor turns on, and suddenly, your PLC starts acting like it’s possessed. Electrical noise might be the culprit.

2. Power Supply Issues

A power supply failure is the PLC equivalent of not having coffee in the morning—nothing works right. Without a stable power supply, your PLC might just randomly reset or shut down, leaving you scratching your head, for most PLC this can wipe their memory.

3. Faulty I/O (Input/Output) Modules

The I/O modules are the PLC’s eyes and hands. When they’re faulty, the PLC might be reading inputs wrong or failing to output signals. If you find yourself looking at a PLC that’s reading an input that isn’t physically there, welcome to ghost-hunting… PLC-style!

Step 1: The Power of Observation

Before diving into the wiring or reprogramming, take a step back and observe. Many times, troubleshooting PLC issues is about seeing what’s out of place. Is there an unusual smell? Yes, electronics give off distinct scents when they’re, well, cooking. Is there a strange noise? A PLC on the verge of failure might sound like it’s practicing beatboxing.

Real-life Example:

A manufacturing plant kept experiencing random shutdowns. The operators noticed the PLC’s lights flickering every time a compressor nearby kicked in. With this observation, they realized the compressor was causing a voltage dip, messing with the PLC’s power supply. A voltage stabilizer later, and voilà—the issue was gone!

Step 2: Analyzing Error Codes Like a Detective

PLC systems come with error codes, which are like the PLC’s way of leaving you bread crumbs to follow. Write down the codes or take a picture before resetting anything. Each code is a clue! If your PLC flashes a “Fault Code 0102,” you might feel like a secret agent cracking the code.

Pro Tip:

Every manufacturer has a unique error code list. Familiarize yourself with it to save time. Some codes mean “replace the module,” while others might suggest a soft reset. Knowing the difference will save you hours—and spare your sanity.

Step 3: Debugging with the Program

PLC troubleshooting is often about finding a bug in the program itself. For instance, an engineer once faced an issue where a conveyor would randomly stop. After hours of testing, he found that the stop condition was mistakenly triggered by a sensor on the other side of the factory floor!

Lesson?

Always check the program logic before diving into the hardware. You can use tools like online monitoring to see what each part of the program is doing in real time. If you see a part of the program behaving oddly, there’s your clue.

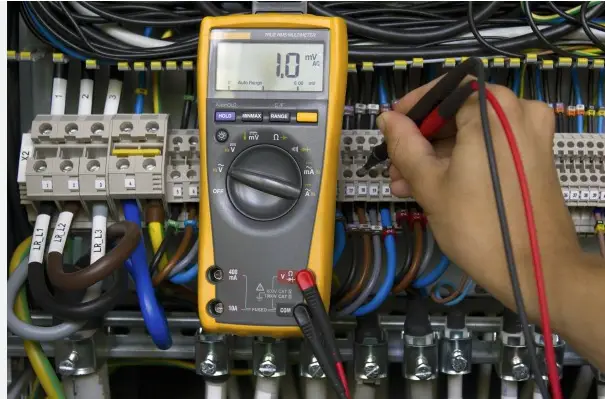

Step 4: Common Hardware Checks

Here’s a quick checklist for those who like to get their hands dirty:

- Power supply connections: Ensure everything is tight and stable.

- I/O Modules: Swap out one module at a time to identify faulty parts.

- Wiring and Terminals: A loose wire could be causing an intermittent issue. Tug lightly on connections to check their security.

Practical Example:

Imagine you’re working on a conveyor, and every time it runs, the PLC faults out. Checking the wiring, you find a loose terminal on a vibration sensor. Tighten it up, and problem solved! Sometimes, it’s the simple things that cause the most headaches.

Step 5: Keep a Log – Because Murphy’s Law is Real

PLC faults can be as unpredictable as cats. One day, they work fine; the next day, they’re throwing error codes for no apparent reason. Keep a fault log to track recurring issues, error codes, and solutions. This way, the next time a fault arises, you’re armed with previous solutions.

Bonus Tip:

If possible, create a digital version of this log that you can share with your team. Future-you (and future colleagues) will thank you!

Wrapping Up: Troubleshooting is a Mindset

Fault finding and troubleshooting in PLCs is all about patience, observation, and occasionally, a sense of humor. As you work through the maze of error codes and test connections, remember this: every fault you fix is one less headache for tomorrow. So, don’t rush; channel your inner detective, take a deep breath, and troubleshoot like a pro.

And next time your PLC decides to throw a tantrum, just smile—because you’re ready.